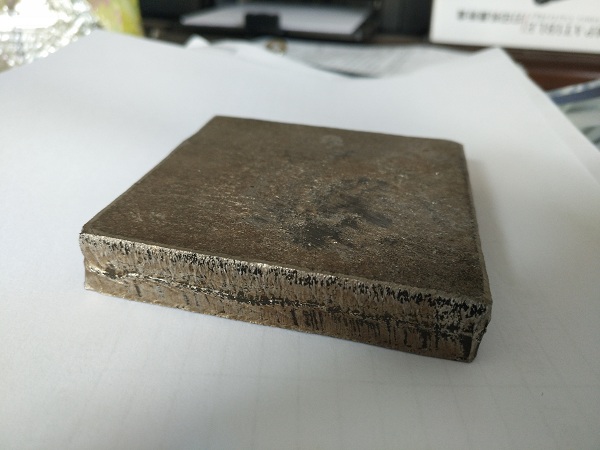

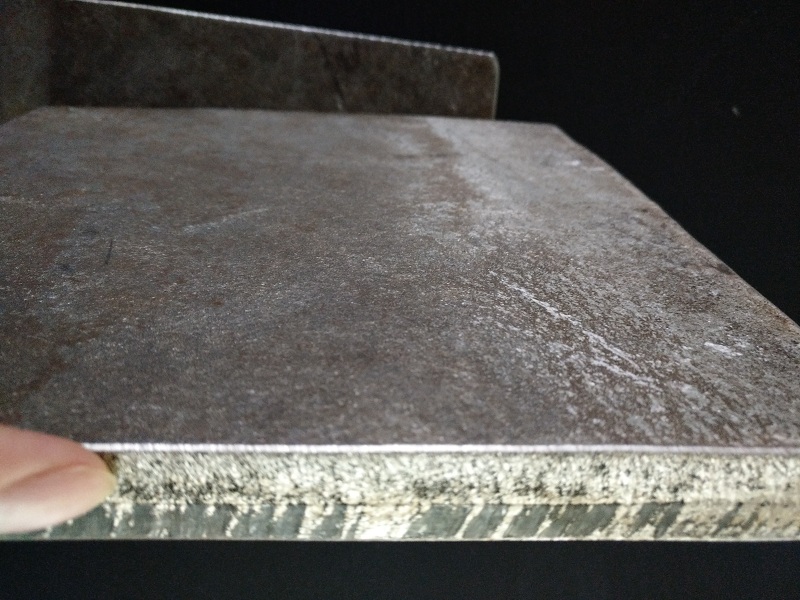

HZY Smooth Surface Chromium Carbide Overlay plate is a bimetal plate that chromium carbide flux cored wire overlaid on the mild steel base plate using submerged arc welding process(modified). There are no cracks and weld beads *For standard/traditional open arc CCO plates which we also produce, please scroll down.

Based on the submerged arc welding process, we improved the process so that the resulting product has no cracks and no weld beads.

Also with the new process, the chemical composition is more flexible.We also offer Fabrication Services like countersunk holes, stud welding, for the creation of all kinds of wear liners.

We offer 2 options of our smooth chromium carbide overlay plate: HZY100 and HZY200.

HZY200 added (V+Mo+W+Nb+Ni+B+Mn....)4-10% HZY200's chemical composition is Cr.:18-35% ; C: 3.0-5.0% ; Si: <1.0% ;(V+Mo+W+Nb+Ni+B+Mn....):4-10% . Hardness:54-60 HRC. Operating temperature: 350 degree(Celsius).

HZY100 is with industrial standard 18-35% chrome content. ASTM G65 procedure A:0.1070g/6000r. Hardness:54-58HRC. Operating temperature: 350 degree(Celsius).

Thickness( For both HZY100 and HZY200):

6+4, 6+6, 8+4, 8+6, 8+8, 10+ 4, 10+6, 10+8, 10+10, 12+4, 12+6, 12+8, 12+12,20+20

Plate size:1000x3000mm

For higher temperature application, we can add niobium or tungsten according to your requirements...

You can choose based on your own needs...

|

Type |

Surface |

Weld beads |

Fusion line |

Cracks |

|

HZY smooth surface chromium carbide overlay plate/HZY100 and HZY200 |

Smooth, low friction. Reduced material buildup |

No weld beads. So material directional flow is not required |

Low dilution with a uniformed fusion line, consistent hardness and micro structure, consistent wear rates |

Minimal cracks. Low residual stress between overlay and base plate. Easy for bending and fabrication |

|

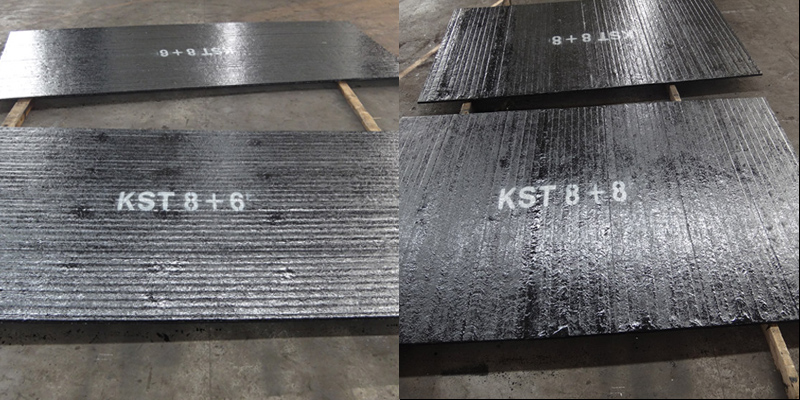

Traditional chromium carbide overlay plate |

Rough, uneven, material buildup |

weld beads. Directional flow over weld beads matters |

High dilution and uneven fusion line. Accelerated wear rates when thickness start to reduce |

Lots of cracks. High residual stress between overlay and base plate. Not easy for bending and fabrication. |

We also provide polished version: shot-blasting, or mirror finished(hand polished) smooth chromium carbide overlay plates...

The most distinctive feature of our smooth surface bi-metallic plate is that it has no weld beads. This feature makes the mirror-like smooth surface possible. Also,there are no cracks, so it's suitable for finer material transporting.

When using traditional chromium carbide overlay plate, some material will stick to the uneven surface, causing material build-up. This problem will decrease your productivity and increase your cost. Our smooth surface overlay plate is made to solve this problem. It has the combined benefits of regular-steel's smooth surface and chromium-carbide-overlay-plate's toughness. So if you have any such requirement, please let us know.

The new technique is based on and improved upon submerged welding process, the wear resistant property has increased. with the same chrome percentage, you get higher wear resistant score.

Wear bars(wear strips):provide protection on buckets for loaders,excavators.240(L)*25(W)*23(8+15);240(L)*40(W)*23(8+15);240(L)*50(W)*23(8+15);240(L)*65(W)*23(8+15);240(L)*80(W)*23(8+15);240(L)*100(W)*23(8+15);240(L)*130(W)*23(8+15);240(L)*150(W)*23(8+15)

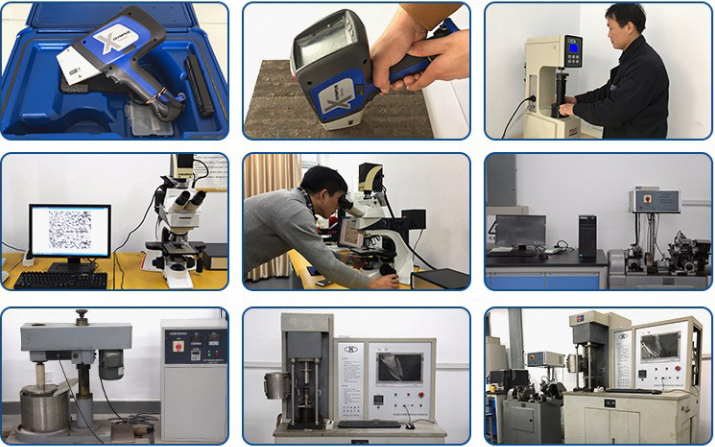

Before testing(polished):

After ASTM G65 process A testing(recorded average weight loss: 0.1070g):

Macrosection of sample:

Micro-structure of weld fusion line(Magnification: X100):

Micro-structure of weld showing upper pass of weld overlay(Magnification: X100):

|

Product Name |

chromium carbide overlay plate, chute liner, chute lining, chromium carbide wear plate, chromium carbide plate, wear plate, wear liner, chromium carbide overlay wear plate, chrome hard facing plate. |

|

HS Code |

8474900000 |

|

Brand |

KST (Chinese pinyin initial of Caster) |

| working temperature |

350 celsius degree....For higher temperature application, please contact us |

|

Base Plate |

Q235B/SS400 |

|

Chemical Composition |

C(%): 3.0-5.0, Cr(%): 17-27, Mn(%): 0.5-2.5, Si(%):0.5-2.5 we can produce higher chrome content 30%-32%...Optional Boron, niobium or tungsten.... |

|

Hardness |

HRC55-60 |

|

Technique |

Open arc |

|

Flatness tolerance |

±3mm/m |

| Thickness tolerance |

±1mm |

|

Main Thicknesses |

4 on 6, 5 on 6, 6 on 6. 4 on 8, 5 on 8, 6 on 8, 7 on 8, 8 on 8. 4 on 10, 5 on 10, 6 on 10, 7 on 10, 8 on 10, 9 on 10, 10 on 10. 4 on 12, 5 on 12, 6 on 12, 7 on 12, 8 on 12, 9 on 12, 10 on 12, 11 on 12, 12 on 12. 4 on 14, 5 on 14, 6 on 14, 7 on 14, 8 on 14, 9 on 14, 10 on 14, 11 on 14, 12 on 14, 13 on 14, 14 on 14. 6 on 20, 8 on 20, 10 on 20……

|

| Plate Size |

plate size:1400*3400mm |

|

Place of Origin |

China |

| Item | Hardness(HRC) | Max service temperature | Abrasion | Impact | Processability | Service life |

| Steel plate | 35-55 | Low | ★ | ★ | ★★ | ★ |

| Hardox | 37-57 | 600 | ★★ | ★★ | ★★★ | ★★ |

| NM | 33-42 | 600 | ★★ | ★★ | ★★★ | ★★ |

| Caster wear plate | 58-62 | 600 | ★★★ | ★★★ | ★★ | ★★★★ |

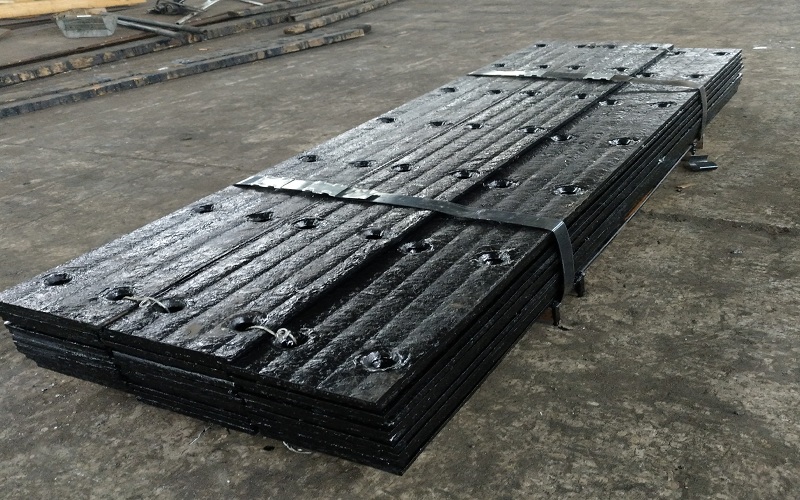

Standard plate size 1400*3400mm

Plate size is actual overlay area

Any alternative base material can be used, such as Q235B or stainless steel plate

Double side welding, overlay can be applied to both sides of the plate, such as 4+6+4 overlay plate

Customized overlay thicknesses can be produced upon request

Can be cut or installed on site

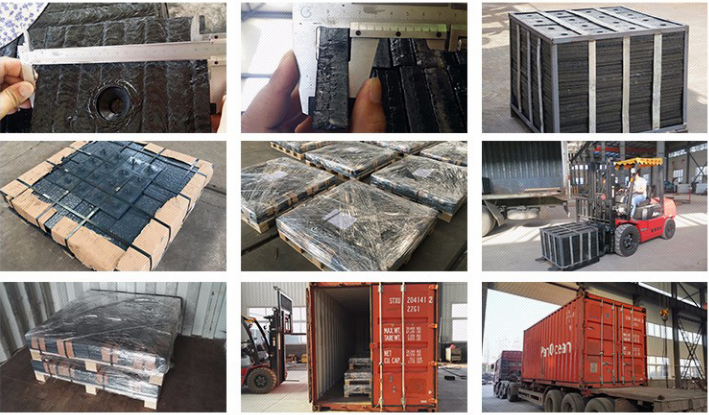

Fabrication services in Jiangsu caster company

Contact: Song Binglin

Phone: +86 13801443885

Tel: 86-514-86826622

Email: jskstsbl@163.com

Add: No.100 Shuangjin Road Jiangdu District, Yangzhou City, Jiangsu Province, China