wear pipe

Caster wear pipe is a bimetal pipe made of seamless steel base pipe onto which chromium carbide overlay is welded with an open arc process. We use an oscillating table with one welding head to arc weld the chromium carbide to the internal(or external, depends on you) of the pipe. We can handle diameters from 120mm and up. We can also bend Chromium Carbide Overlay Plate to form pipes. The overlay is deposited perpendicular to the flow of material through the pipe resulting in a longer wear life.

wear elbow: Our Chromium Carbide Overlay Elbows are welded with the same material. Overlay is deposited in either a single pass application which is 4mm-6mm thickness or a double pass application which is 8mm - 12mm in thickness. Wear life of our Overlay Pipe can be up to 15 to 1 over standard wear pipe. The longer wear life of our products reduce maintenance hassles, costly down time, and material loss.

Wear Pipe types

1.Steel pipe with regular base material + overlay, pipes are welded using oscillating table with one welding head to arc weld the chromium carbide to the base material.

2.Bending the wear plate into round pipe.

3.Assembling the wear plate into square pipe.

automatic welding, metallurgical bonding, available to weld the minimum pipe diameter of 120mm and maximum pipe length of 3000mm.

Wear Elbow types

1.Weld directly on the elbow wall

2.wear plate used to make joint form

Square to Round Transition

Wear plate used to make tube with round top and square bottom.

|

Product Name |

chromium carbide overlay alloyed anti wear tube |

|

Brand |

caster |

|

Base Plate |

Q235/Q345 |

|

Hardfacing layer |

High chromium high carbide overlay (Hard layer face out or face in) |

|

Chemical Composition |

C(%): 3.0-5.0, Cr(%): 18-25, Mn(%): 2.0-3.0, B(%): 0.7-1.0 |

|

Hardness |

HRC58-62 |

|

Surface Treatment |

Hardfacing, clading, coated |

|

Technique |

Hardfacing, open arc welding, submerged arc welding |

|

Minimum Inner Diameter |

120mm |

|

Wear Resistance |

High wear resistance |

| Thickness |

8+4 and above |

|

Place of Origin |

China |

|

Application |

Mining, Steel, Cement, Power, Port, etc. |

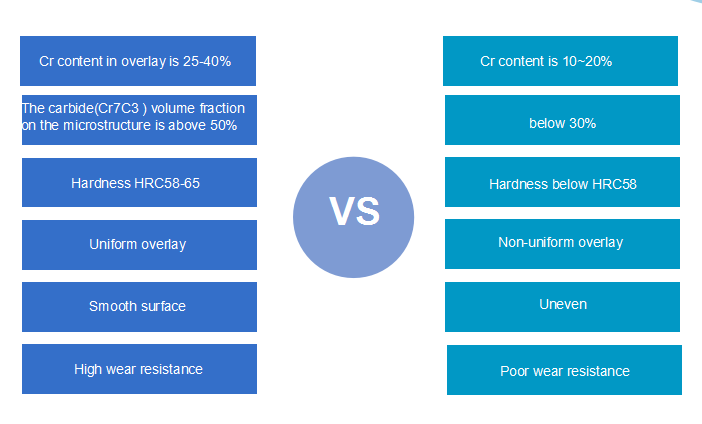

Our Advantages

Contact: Song Binglin

Phone: +86 13801443885

Tel: 86-514-86826622

Email: jskstsbl@163.com

Add: No.100 Shuangjin Road Jiangdu District, Yangzhou City, Jiangsu Province, China