chute liner

Caster chute liner is wear liner with countersunk holes or welded bolts, made from chromium carbide overlay plate, cutting according to your drawings. We also produce CCO pipe.

It gains its wear-resistant properties from chrome carbide, embedded in a stable matrix. Their balanced formulation and excellent price-performance ratio make our composite wear plates the standard solution for a wide range of wear problems.

We also offer Fabrication Services(cutting, drilling, countersunk holes, stud welding) for the creation of all kinds of wear liners.

Pricing & Availability:

Products are not in stock. we produce according to your order.

Quality warranty:

If the quality doesn't match your expectation, you can always ask for refund or replacements.

You're welcome to visit us for inspection purpose. Being honest is what keep our business humming.

We also produce Smooth Surface Wear Plate:

Advantage of smooth surface: less friction. disadvantage: hard to fabricate.

Technical Specifications & Chemical Composition:

|

Product Name |

chute liner |

|

HS Code |

8474900000 |

|

Brand |

Caster (Chinese pinyin initial: KST) |

|

Base Plate |

Q235B/SS400 |

|

Hardfacing layer |

Chromium carbide overlay, weld overlay |

|

Chemical Composition |

C(%): 3.0-5.0, Cr(%): 22-27, Mn(%): 2.0-3.0, B(%): 0.7-1.0 Chrome content can be even higher like 30% or 32%, but the cost will increase accordingly. |

|

Microstructure |

The carbide (Cr7C3) volume fraction on the microstructure is above 50%. |

|

Hardness |

HRC58-62 |

|

Surface Treatment |

Overlay, Hardfacing, cladding, coated. |

|

Technique |

Hardfacing, open arc welding, submerged arc welding. |

|

Wear Resistance |

High wear resistance, 30 times higher than low carbon steel and 12 times than heat treated steel. |

|

Impact Resistance |

Medium. |

|

Flatness tolerance |

±3mm/m. |

|

Thickness tolerance |

Uniform overlay thickness, with tolerance within ±0.5mm. |

|

Main Thicknesses |

3 on 5, 4 on 6, 5 on 6, 6 on 6. 4 on 8, 5 on 8, 6 on 8, 7 on 8, 8 on 8. 4 on 10, 5 on 10, 6 on 10, 7 on 10, 8 on 10, 9 on 10, 10 on 10. 4 on 12, 5 on 12, 6 on 12, 7 on 12, 8 on 12, 9 on 12, 10 on 12, 11 on 12, 12 on 12. 4 on 14, 5 on 14, 6 on 14, 7 on 14, 8 on 14, 9 on 14, 10 on 14, 11 on 14, 12 on 14, 13 on 14, 14 on 14. 6 on 20, 8 on 20, 10 on 20…… Customized. |

|

Plate Size |

Standard chromium carbide overlay wear plate size:1400*3400mm, this is the maximal size. If you want something larger, we can weld 2 plates together. And in the standard size, the plate is cheapest, because there's no cutting and other costs. |

|

Place of Origin |

China. |

|

Application |

grinding mill liner, hopper liner, silo liner, chute liner, chute lining, crusher liner, etc. |

Performance comparison between Caster chute liner and other wear plate:

| Item | Hardness(HRC) | Max service temperature | Abrasion | Impact | Processibility | Service life |

| Steel plate | 35-55 | Low | ★ | ★ | ★★ | ★ |

| Hardox | 37-57 | 600 | ★★ | ★★ | ★★★ | ★★ |

| NM | 33-42 | 600 | ★★ | ★★ | ★★★ | ★★ |

| Caster chute liner | 58-62 | 600 | ★★★ | ★★★ | ★★ | ★★★★ |

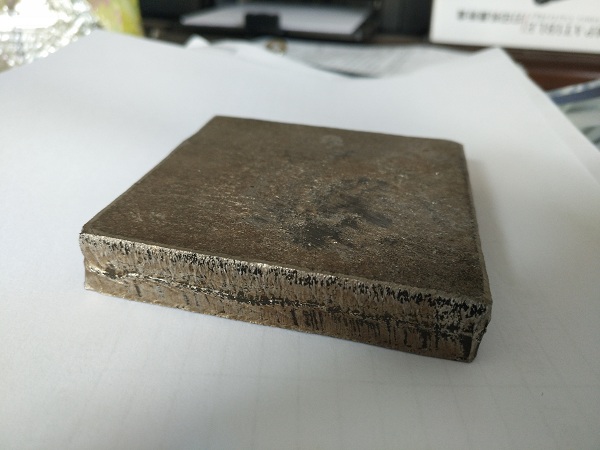

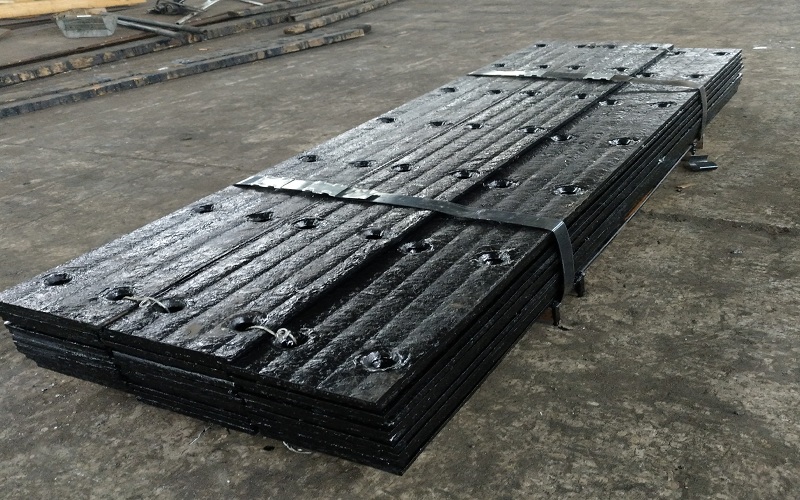

Product display of our chute lining

Pictures of manufacturing process

Field application

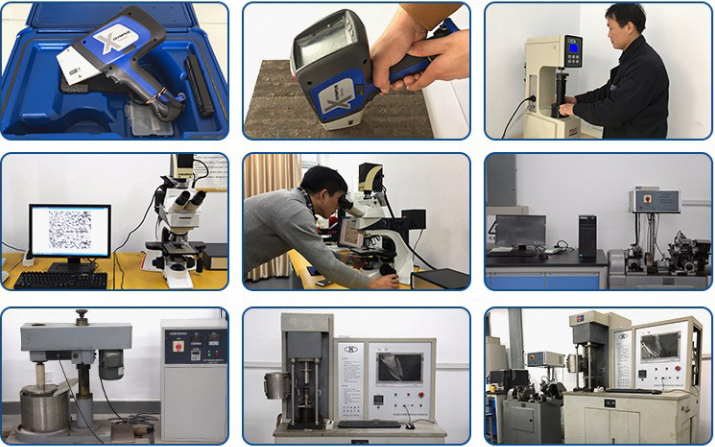

Quality inspection

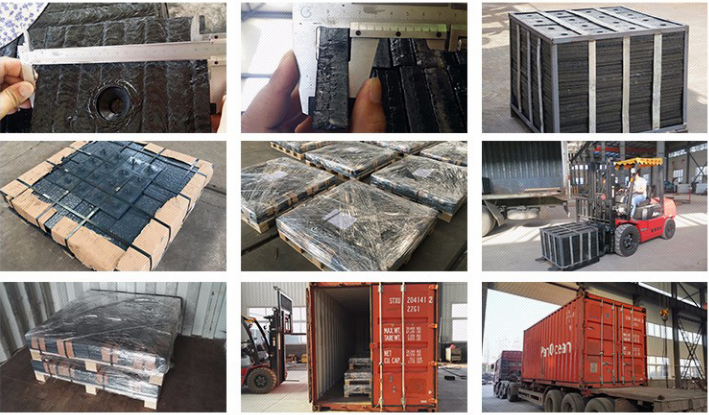

Packaging & Shipping

Packaging: Steel pallet, Non fumigation pallets,Customized

Packaging Size: 1.4*3.4, 1.4*.3.0, customized.

Delivery Detail: Generally it is 5-10 days, it is according to quantity.

Industry application of chute liner

Cement industry

The cement industry has provided our biggest customer base since our founding. the severe abrasion experienced in cement mills, chutes and hoppers, gives the industry a serious need for equipment protections. Our chromium carbide overlay wear plate/lining provide the best solutions in the world for cement mill rollers of all types.

Mining industry

Face it, no matter what minerals you are mining, there is no escaping the abrasion experienced by mining equipment. not only can we reduce equipment damage to hopper and chutes, but our chromium carbide overlay wear plate lining can significantly extend the life of dump trucks, excavating equipment, and transport equipment.

Coal power industry

the reliable movement of coal is crucial to the coal power industry. when chutes and hoppers need to be replaced, the replacement and repair service costs are expensive, and the downtime can hurt the bottom line. reduce the down time, and extend the life of your equipment with solutions from CASTER chromium carbide overlay wear plate.

Steel industry

the steel industry experiences great wear and tear on its equipment that transports raw ore into its processing areas, CASTRT chromium carbide overlay wear plate protection on chutes and hoppers reduces down time and replacement costs.

Construction Equipment

Wear resistant steel plate(abrasion resistant steel plate) for the protection of the active surfaces of many types of construction equipment. Companies that use dump trucks, bulldozers, and other vehicles used in the construction industry are also our customers.

Other industries

the chromium carbide overlay, hardfacing,or protective cladding services provided by our company can extend the service life of equipment used in many other industries, where heavy equipment experiences wear and abrasion. any industry using hoppers and chutes can benefit from the protection of our chromium carbide overlay wear plate.

After sales

Our company has a professional after-sales service team, with many years of experience not only on hardfacing products and applications, but also on the operation of application equipment. We are able to quickly solve customer’s problems.If there are any quality problems, the responsible person will provide reasonable solutions within 12 hours after being notified.

Contact: Song Binglin

Phone: +86 13801443885

Tel: 86-514-86826622

Email: jskstsbl@163.com

Add: No.100 Shuangjin Road Jiangdu District, Yangzhou City, Jiangsu Province, China